I got an opportunity to participate in the Punished Props Secret Santa Exchange for the first time in 2019, and I put together a 3D printed M6G Magnum from Halo. It featured a working slide and trigger, as well as a removable clip. It was a great pleasure to join in on the prop making fun and deliver not one, but two completed pistols to the awesome @tim_makes. My friend, Tom, helped me with the second model. Painting is not my strong suit since I have red-green colorblindness and it makes color matching difficult.

Model Details

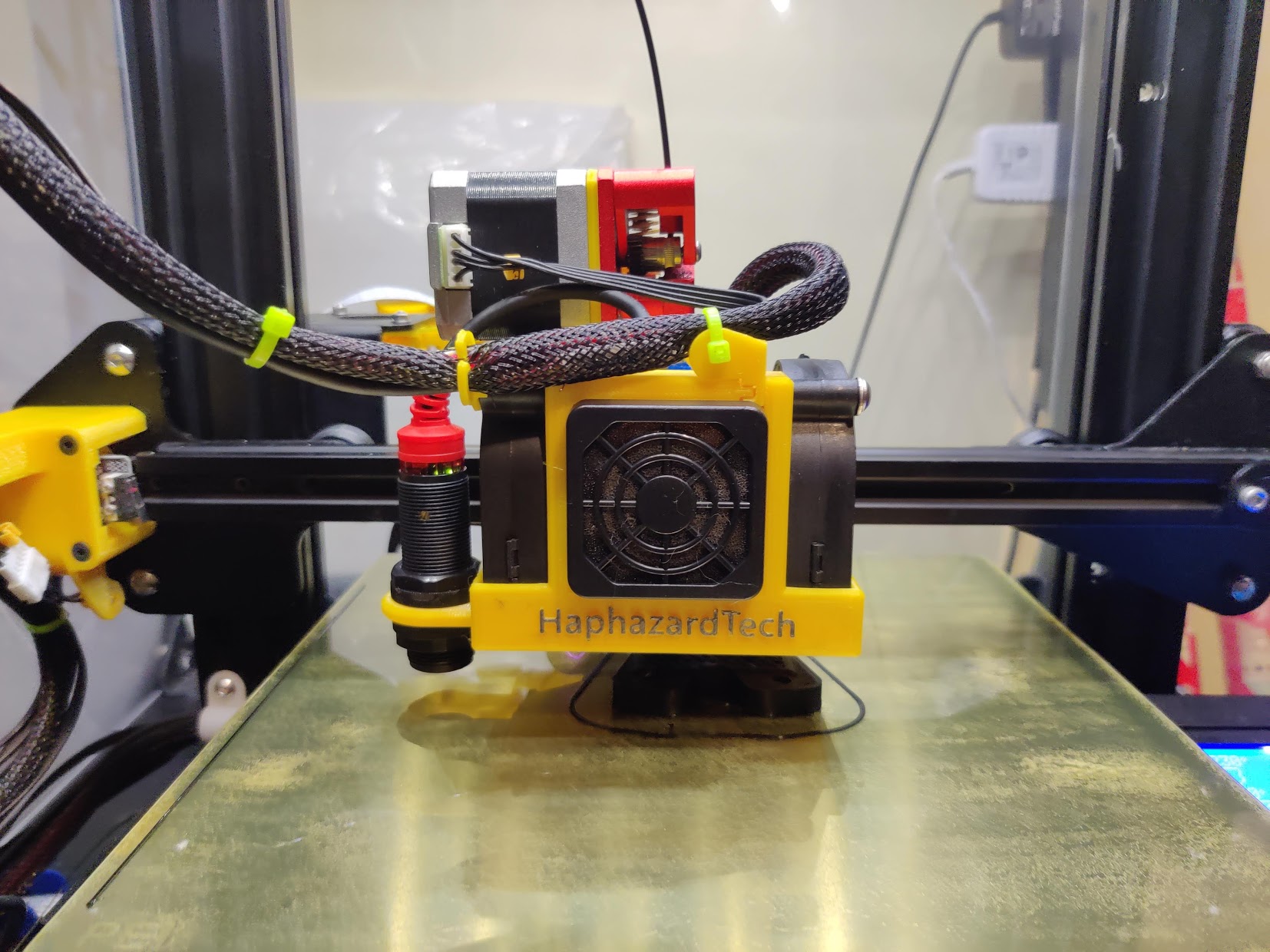

Printer: Creality Ender 3

3D Files: M6D Magnum Sidearm on Thingiverse

Model 1 (Printed on my Ender 3) –

Material: 3D Solutech Silver PLA (Print #1), Filament Friday Black PLA (Print #2)

Paint: Poly-Props SEAL Prime – Black, Poly-Props HEX-ART Metallics – Steel, Poly-Props Valour Clear Coat

Filler: Smooth-On XTC-3D, Bondo Glazing and Spot Putty

Other Materials: Hand-made springs from spring steel wire, Bob Smith CA Glue

Model 2 (Printed on Tom’s Ender 3) –

Material: Inland Blue PLA

Paint: Rustoleum Black Primer, Angelus Acrylic Paints, Angelus Clear Coat

Filler: Bondo Glazing and Spot Putty

Other Materials: Hand-made springs from spring steel wire, Gorilla CA Glue

Build Details

Halo M6D Magnum Replicas, prepared for shipment to @tim_makes

This was my first major 3D printed project, despite having my Ender 3 for some time. I ran into a lot of issues with my printer not being calibrated correctly and the angles were not true. Along with a bit of vibration in the printer and cable management issues, printing was fraught with problems. However, most of my problems were solved and minor defects could be covered during finishing.

First Prototype (Failed)

This one had a number of issues, not the least of which was jitters in the surface and curling issues which caused assembly issues. I believe most parts were discarded. Technically, this was the second model I printed. My original plan involved a stationary M6D that I printed hollow to install electronics, but it didn’t pay off. The model was structurally weak and I didn’t know enough about layering back then.

This was (part of) the first-first prototype model I printed.

Preparing model for priming. Bondo Spot Putty was used to even out the uneven surfaces left by the XTC-3D resin. I can’t seem to find any photos I took with just the XTC-3D layer applied.

The slide was assembled after the main body was primed. You can see the layer of spot putty on the slide handle.

Primed main M6D body.

The HexArt Metallics “Steel” paint sputtered while spraying, which actually left a cool texture behind. Everything was sealed up later with the Valour Clear Coat.