I started building a Working Stargate Mk2 with Working DHD and SFX, designed by Glitch. I’m slowly working my way through the Arduino and stepper motor configuration. The documentation for this project is not spectacular, but the framework is there and it was a fun puzzle to figure out. It’s definitely not perfect, but still workable.

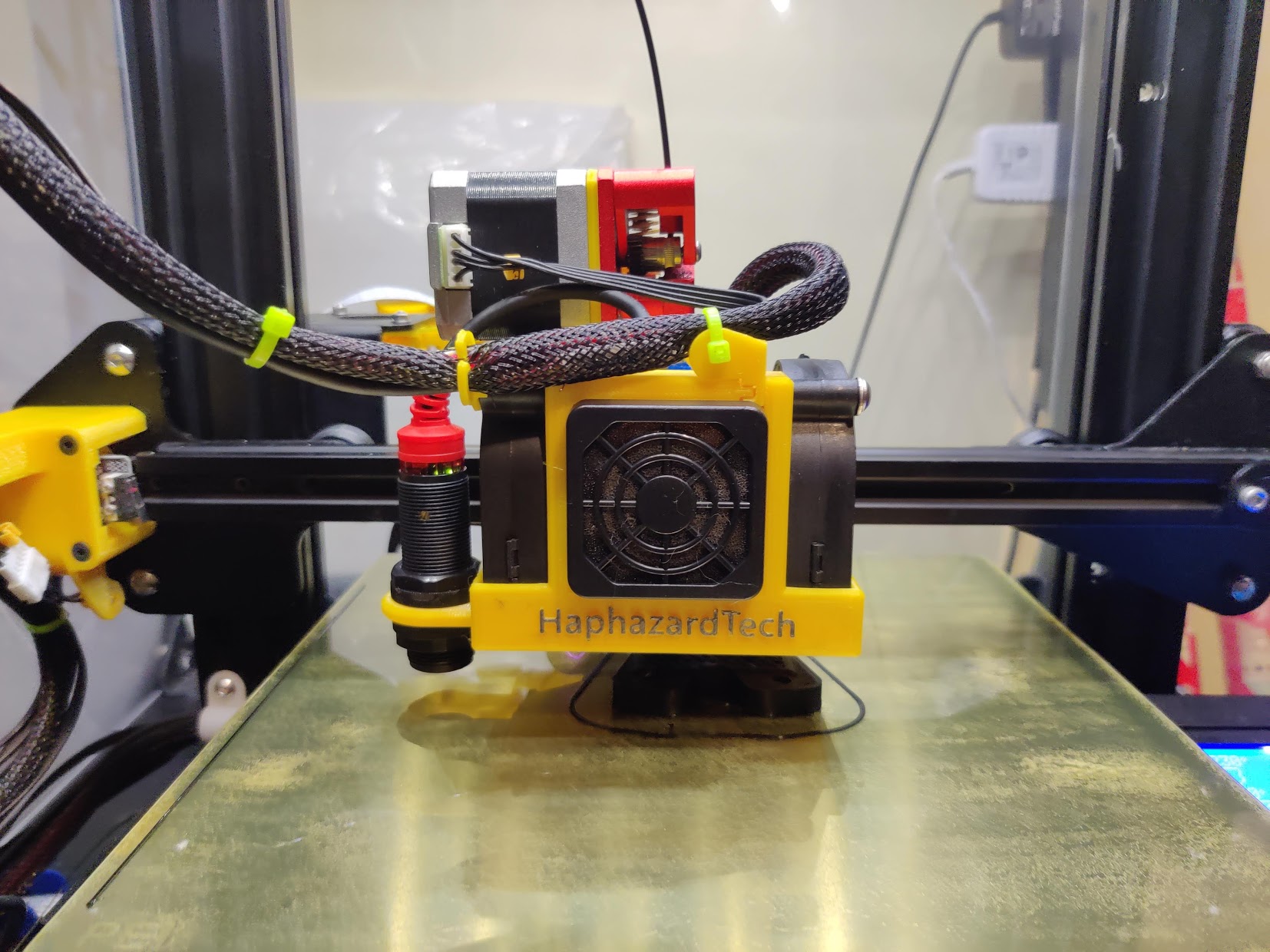

Printer: Creality Ender 3

Filament: HATCHBOX PLA (Silver), Overture PETC (Black), Duramic PETG (White)

Adhesive: Bob Smith Thick CA Glue

Electronics: Arduino Uno, Arduino Nano, DFPlayer MP3 Player, Nema-17 Stepper Motor, Miscellaneous Electronic Components, 24AWG Stranded Copper Silicone Wire